Precision and complex packaging SMD PCBA OEM

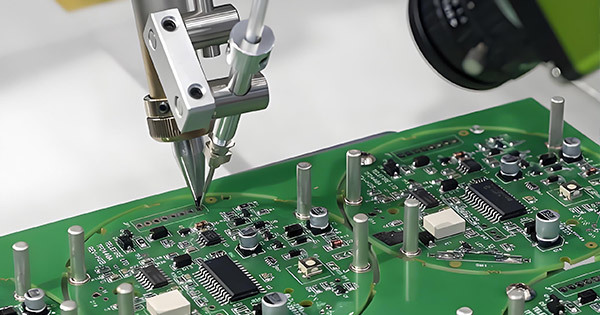

The product's chip components are precisely packaged and come in many varieties. The smallest chip component package is 01005, and the BGA ball pitch can be up to 2.0mm. The product has high requirements for cleanliness and the quality of welding accessories. It tests process control and technical capabilities, and has high requirements for the processing accuracy of related equipment on the chip production line.

Category:

Products

Keywords:

Onte Electronic Technology

PCBA comprehensive solution

Precision and complex packaging SMD PCBA OEM

The product's chip components are precisely packaged and come in many varieties. The smallest chip component package is 01005, and the BGA ball pitch can be up to 2.0mm. The product has high requirements for cleanliness and the quality of welding accessories. It tests process control and technical capabilities, and has high requirements for the processing accuracy of related equipment on the chip production line.

SERVICE COMMITMENT

R&D Cooperation

8-hour response, 24-hour standby

Product Quality

100% qualified rate of finished products

Order delivery time

Strictly follow customer requirements

After-Sale Service:

8-hour response, 24-hour standby

Recommended Products

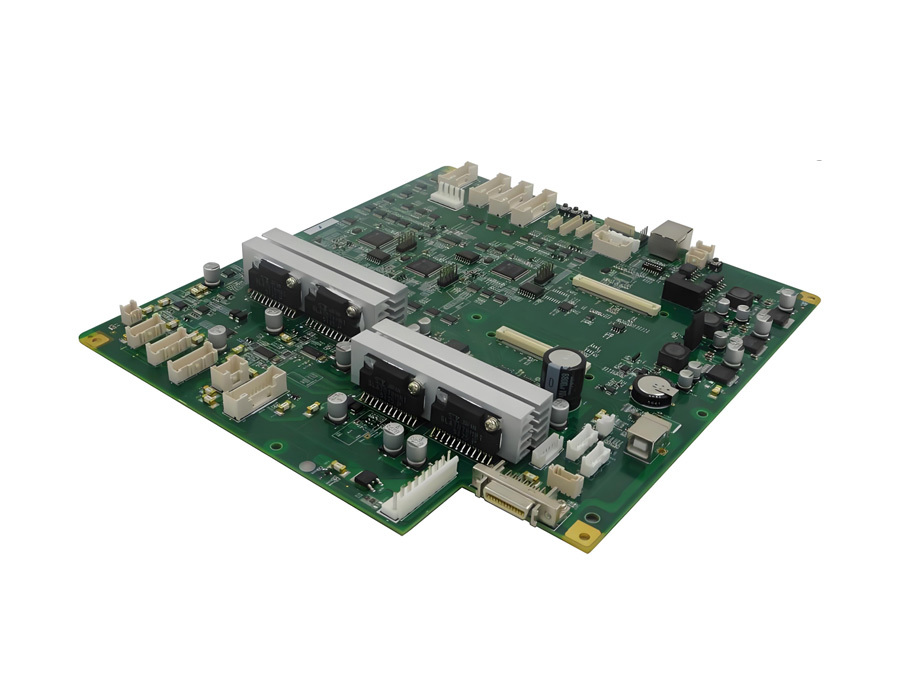

Double-sided SMD + complex package plug-in components PCBA OEM

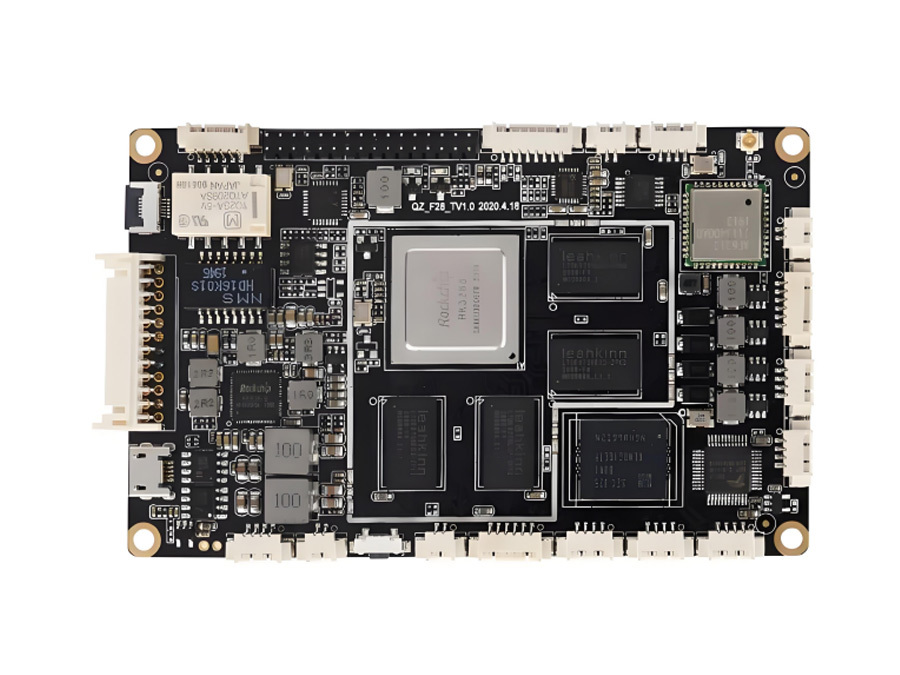

Precision and complex packaging SMD PCBA OEM

Multi-layer, large-size PCBA OEM and OEM

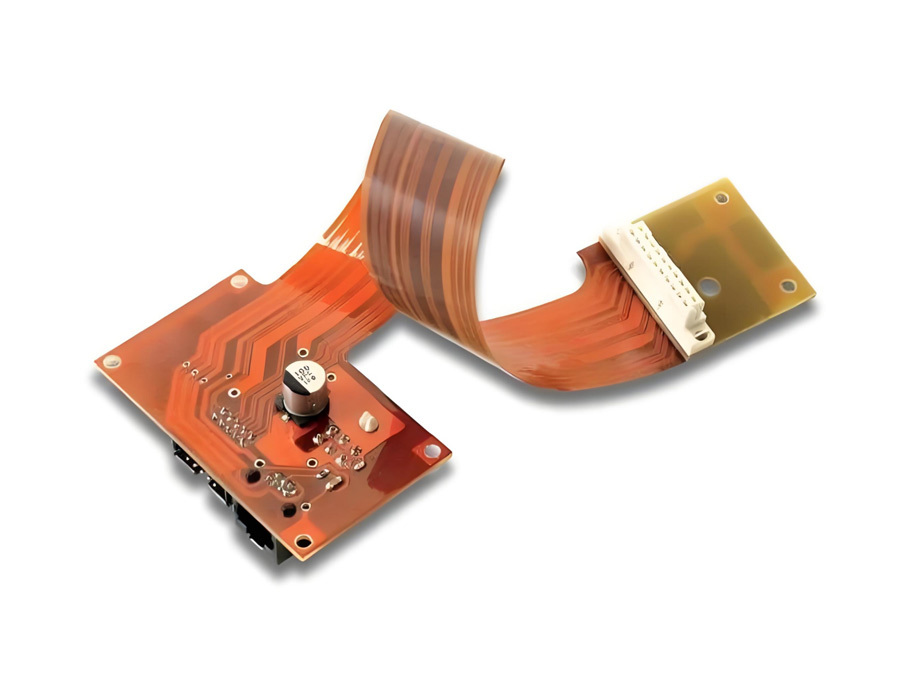

FPC flexible circuit board OEM

Global partners

Our printed circuit board assembly (PCBA) and box build services are widely trusted by global customers for many years.

Product Consultation

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!