PCBA CONTRACT MANUFACTURER

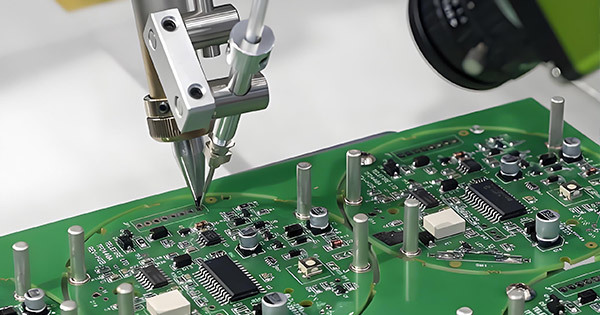

Electronic product OEM (R&D cooperation, material procurement, SMT surface mount, plug-in, testing, UV paint three proof coating, assembly, aging, functional maintenance, etc.)

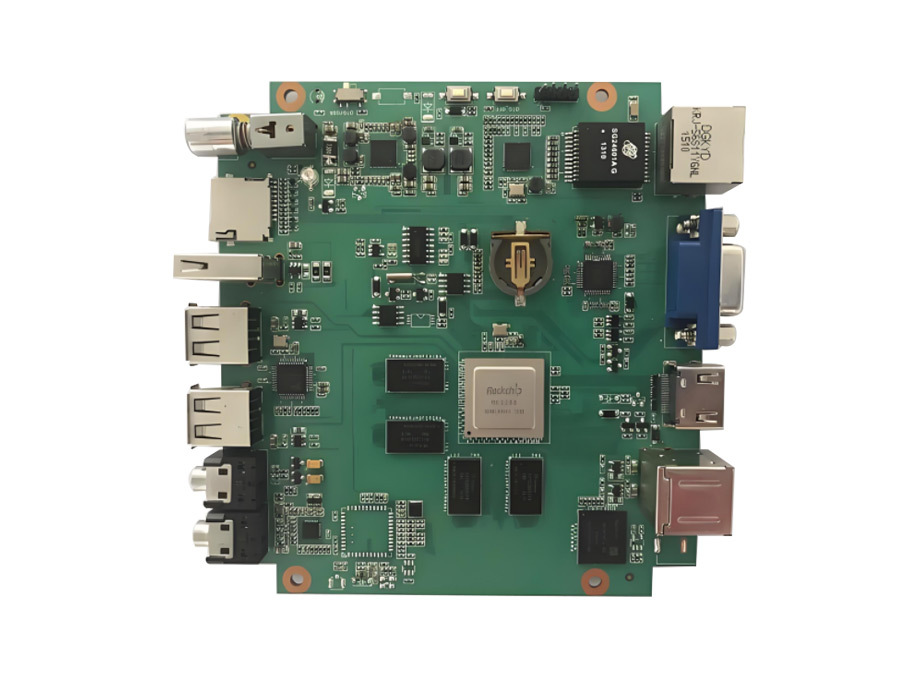

Security Electronics

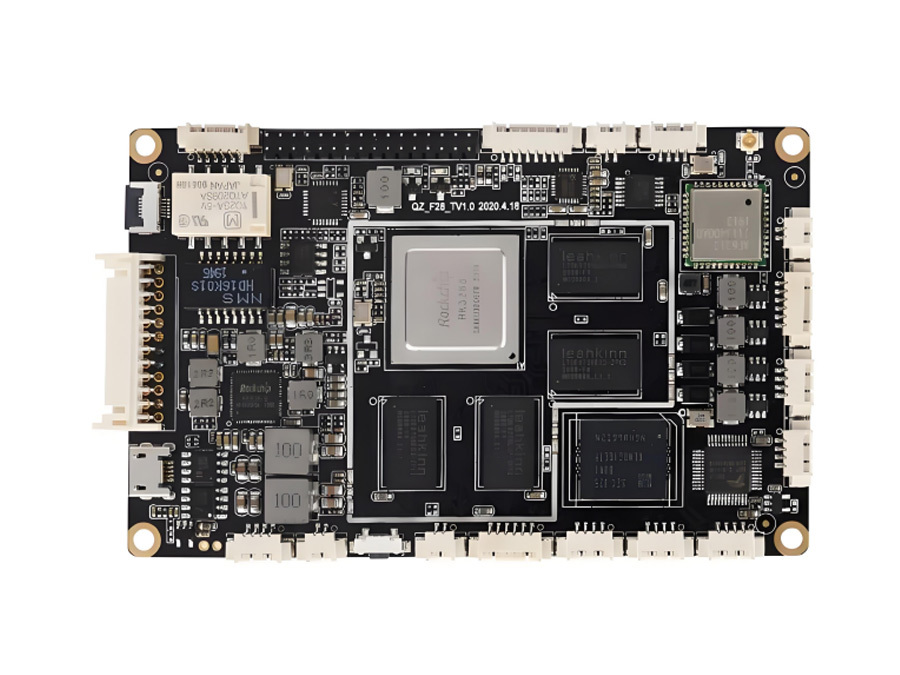

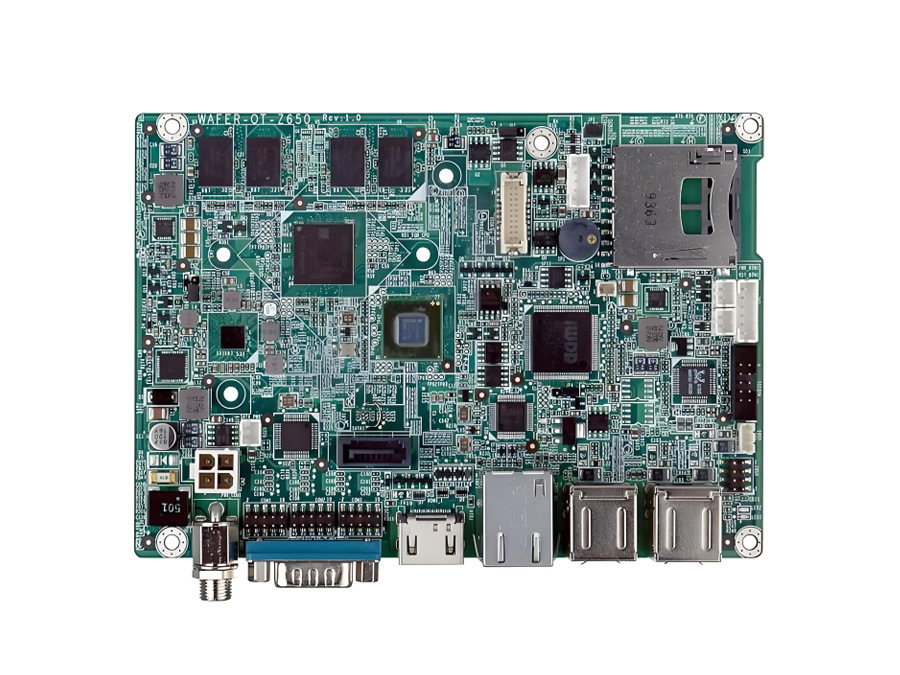

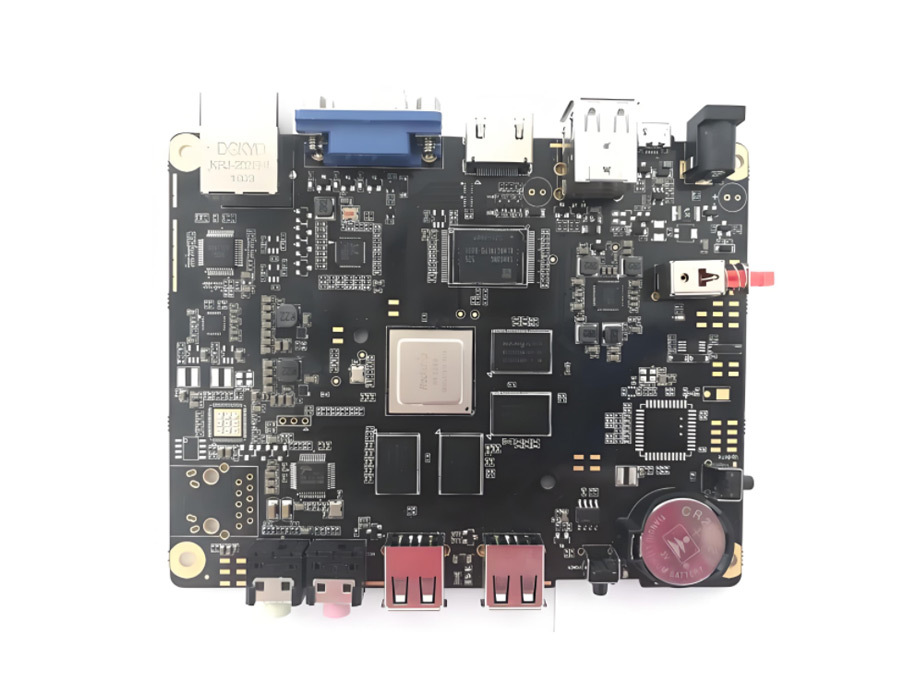

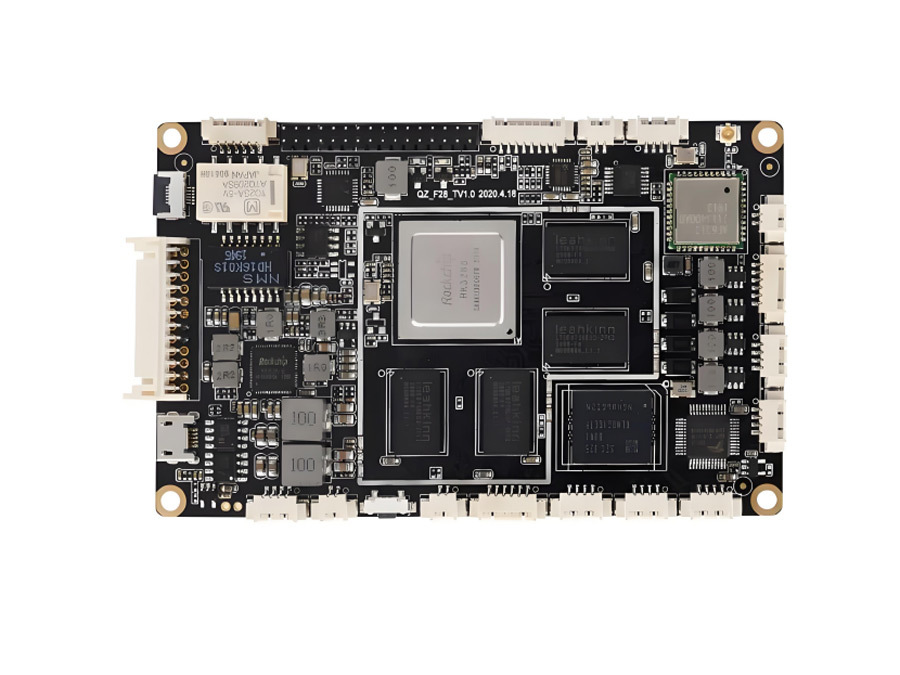

Android motherboard

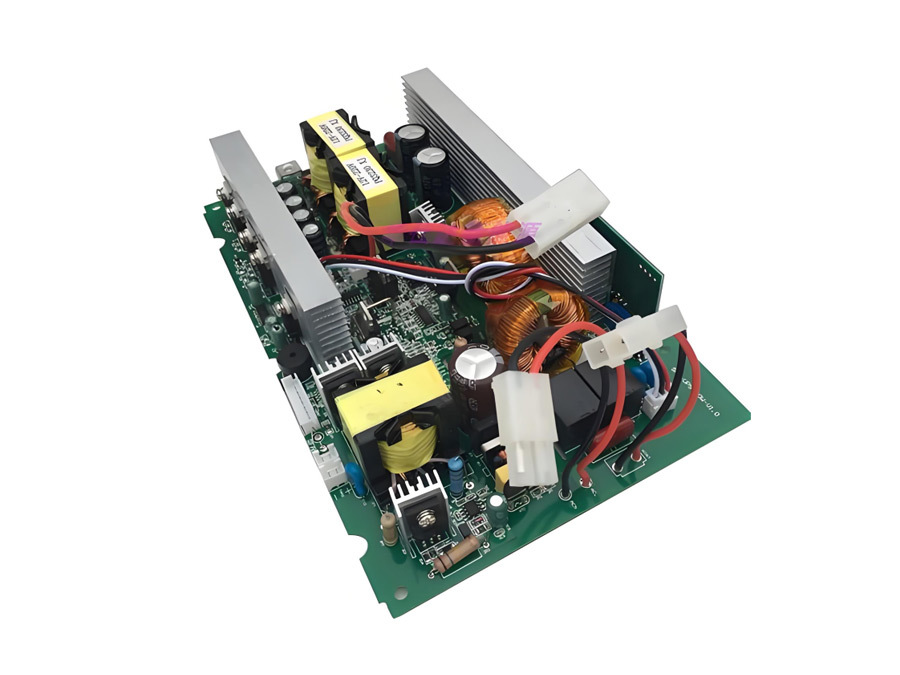

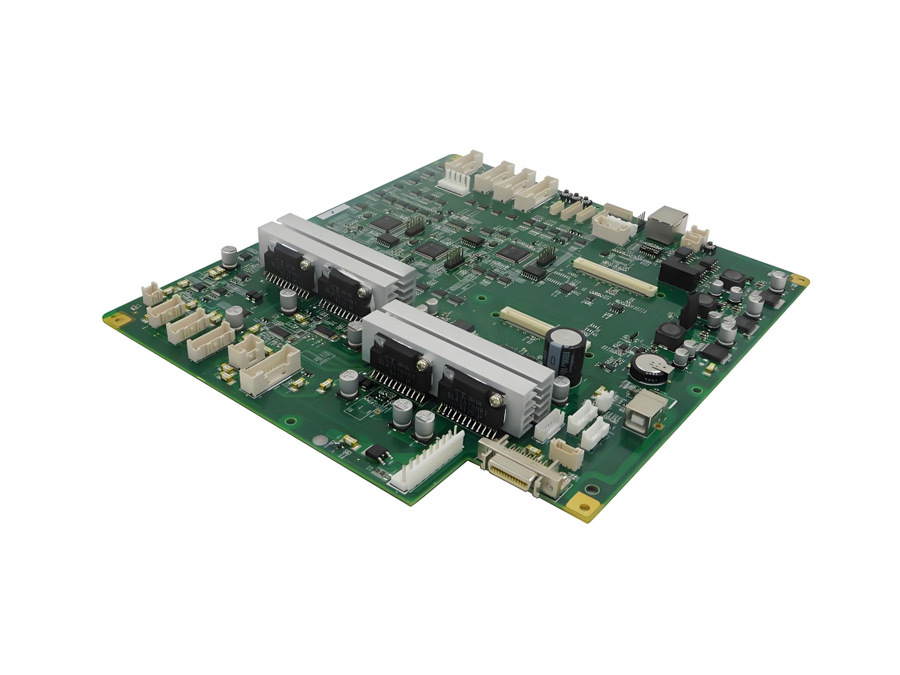

Power Inverter

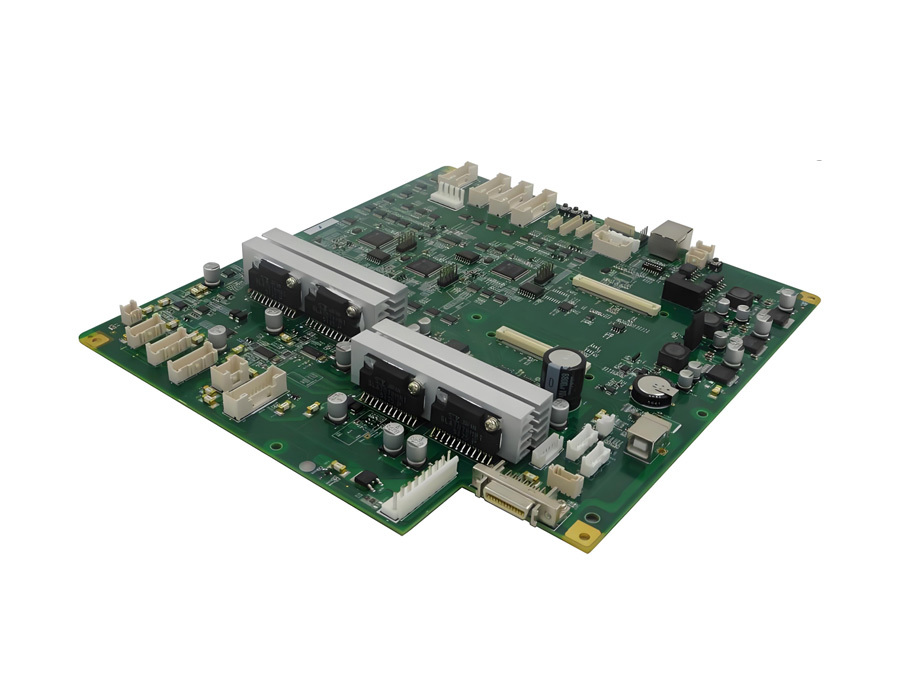

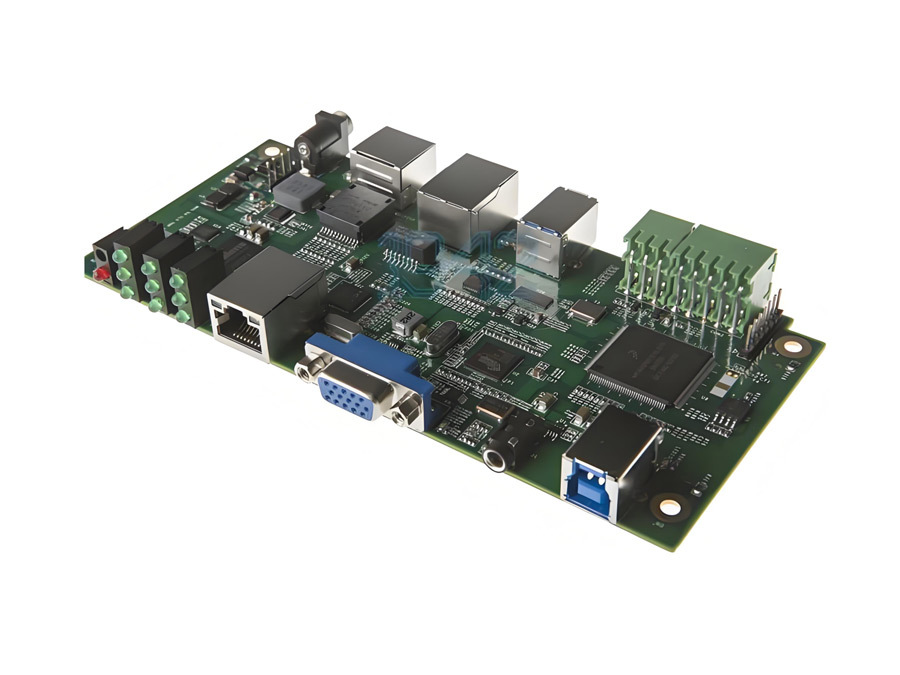

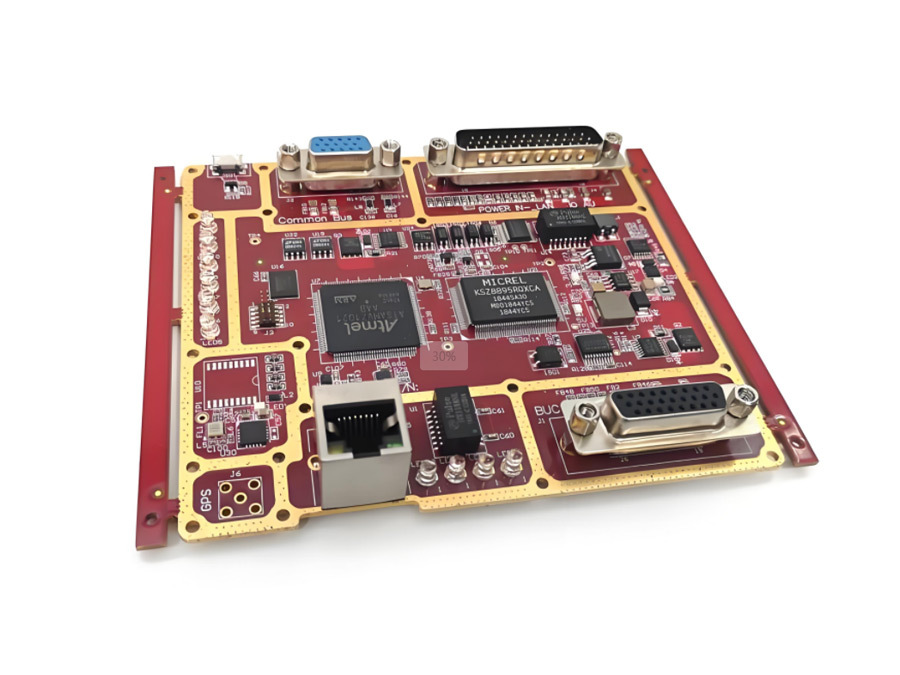

Industrial control motherboard

Advertising machine

Mechanical Control

Automotive Electronics

Communications equipment

Image acquisition

Network equipment

IoT devices

Medical Electronics

Smart Home

Double-sided SMD + complex package plug-in components PCBA OEM

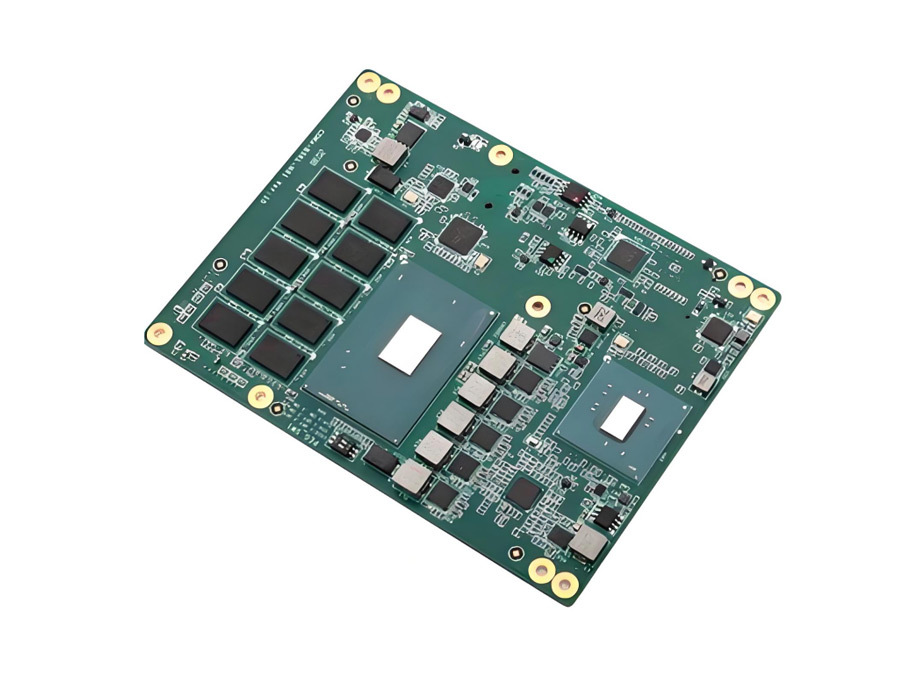

Precision and complex packaging SMD PCBA OEM

Multi-layer, large-size PCBA OEM and OEM

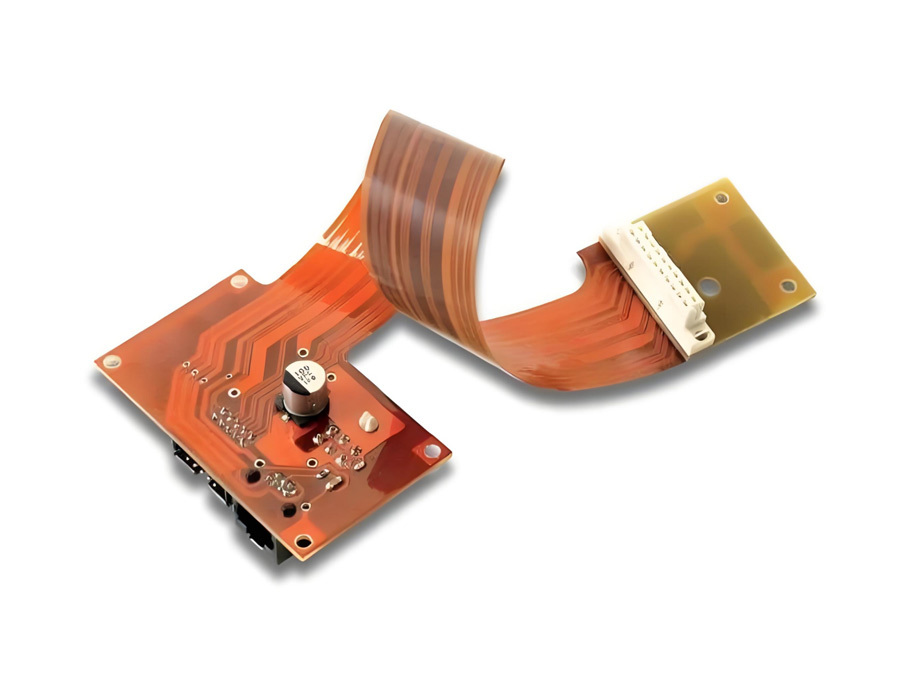

FPC flexible circuit board OEM