Why We Excel Beyond PCBA Manufacturing: The Power of DFX and Smart Processes

At our core, we’re more than just a PCBA manufacturer. We combine cutting-edge R&D expertise with a deep understanding of every production stage, delivering exceptional results through Design for X (DFX) and intelligent manufacturing. Here’s how we stand out.

Aug 20,2025

What is Design for X (DFX)?

DFX is a strategic approach to product design that optimizes every aspect of the product lifecycle—whether it’s manufacturing, assembly, testing, reliability, or cost. By addressing these factors early in the design phase, we minimize costly revisions, enhance quality, and accelerate time-to-market.

Key DFX Approaches We Champion:

- Design for Manufacturability (DFM): Simplifies production to reduce complexity and costs.

- Design for Assembly (DFA): Streamlines assembly to save time and prevent errors.

- Design for Testability (DFT): Ensures products are easy to test, cutting testing time and costs.

- Design for Reliability (DFR): Boosts product durability and lifespan.

Why DFX Matters:

- Cost Savings: 70%-95% of a product’s lifecycle costs are locked in during the design phase. DFX tackles issues early to avoid expensive fixes later.

- Faster Production: Optimized designs reduce iterations, speeding up delivery.

- Superior Quality: By prioritizing reliability and testability, we meet and exceed industry standards.

- Seamless Collaboration: DFX fosters teamwork across design, manufacturing, and supply chain, breaking down silos for better outcomes.

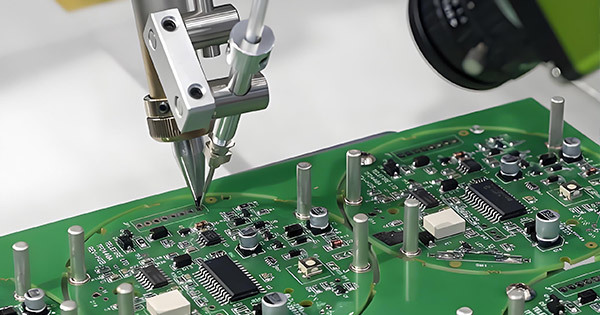

Our PCBA Process: Precision at Every Step

Our state-of-the-art PCBA process ensures quality, efficiency, and traceability. Here’s a glimpse into the key steps:

- Board Loading: Bare PCBs are securely fixed to carriers to prevent misalignment during surface-mount technology (SMT) processes, ensuring precise component placement.

- Laser Marking: Each PCB is marked with a unique QR code containing production batch, model, and manufacturer details for traceability and quality control.

- Solder Paste Printing: Using high-precision stainless steel stencils (0.08 ± 0.005 mm thickness, SMT laser + electropolishing), we apply solder paste with exceptional accuracy. High-quality solder paste ensures excellent solderability.

- Solder Paste Inspection (SPI): Advanced systems detect issues like misalignment, insufficient paste, or short circuits, ensuring flawless application.

- Surface-Mount Technology (SMT): Using top-tier Panasonic or Samsung machines, we achieve high-precision component placement with minimal errors.

- Visual Inspection: Our operators meticulously verify initial PCBA quality, correcting any issues like missing or misaligned components.

- Reflow Soldering: PCBs pass through a precision-controlled oven (±1°C accuracy) with tailored temperature profiles (preheating, constant temperature, reflow, cooling) for robust solder joints.

- Automated Optical Inspection (AOI): High-precision equipment (±15 µm) identifies defects like misalignment or missing QR codes.

- Through-Hole Insertion (DIP): Automated insertion handles most components, while non-standard parts (e.g., transformers, heat sinks) are manually inserted and soldered via wave or hand soldering.

- X-Ray Inspection: Critical for BGA, QFN, and RF products, X-ray scanning ensures perfect soldering and placement.

- Packaging and Storage: PCBs are coated with moisture-resistant or conformal coatings, vacuum-packed with anti-static materials, labeled, and stored for maximum protection.

Embracing Industry 4.0 for Smarter Manufacturing

We’re at the forefront of Industry 4.0, integrating IoT, 5G, AI-driven inspection, and robotics to create a smarter, more efficient production line. These technologies enable real-time data processing, predictive quality control, and progress toward fully automated, unmanned manufacturing.

Why Choose Us?

Our commitment to DFX and intelligent manufacturing distinguishes us. By blending innovative design with precision processes and Industry 4.0 technologies, we deliver high-quality PCBAs that are both cost-effective and reliable, and ready for the future.

Ready to elevate your next project? Contact us today to learn how we can bring your vision to life.