The genesis of integrated circuit chips.

Integrated circuit chips are an important component of modern electronic technology, consisting of a large number of miniature electronic components (such as transistors, resistors, capacitors, etc.) and connecting circuits. The birth of integrated circuit chips cannot be separated from the progress of electronic technology and the development process of integrated circuits.

Feb 26,2025

Integrated circuit chips are an essential component of modern electronic technology. They consist of many miniature electronic components (such as transistors, resistors, capacitors, etc.) and connecting circuits. The birth of integrated circuit chips cannot be separated from the progress of electronic technology and the development process of integrated circuits.

The birth of integrated circuit chips can be traced back to the 1960s. At that time, electronic technology was developing rapidly, and people had higher requirements for integrating electronic devices. Early integrated circuit chips used small-scale integrated circuits (SSIs), typically consisting of dozens of transistors. With the development of technology, people have begun to try large-scale integrated circuits (LSI), which can incorporate thousands of transistors and have more complex functions. In the 1970s, colossal scale integrated circuits (VLSI) emerged, capable of integrating tens of thousands of transistors.

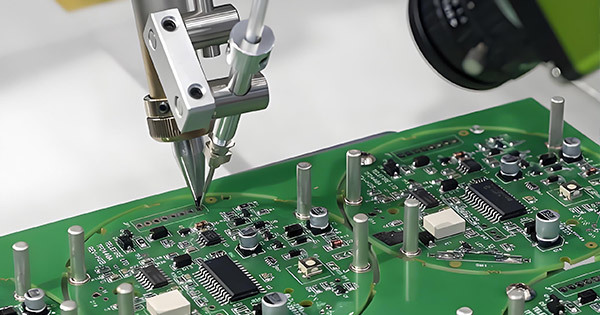

The design and manufacturing of integrated circuit chips is a complex process. Firstly, designers need to design circuits and layouts based on the functional requirements of the chip. Designers use computer-aided design (CAD) software to complete the design of circuit diagrams and layout diagrams. After the design is completed, a mask needs to be made. A mask is a template used for manufacturing chips, which is covered with a layer of photoresist on a silicon wafer. Then, the circuit pattern is engraved on the photoresist using photolithography technology.

After making the mask, the next step is to manufacture the chip. During the manufacturing process, the first step is to prepare the silicon wafer. Silicon wafer is the basic material used to make integrated circuit chips with good conductivity and insulation properties. During manufacturing, it is necessary to clean and coat the silicon wafer. Then, photolithography technology transfers the circuit pattern onto the silicon wafer. After the transfer is completed, further process steps, such as etching and deposition, are required to form the structure and components of the circuit. Finally, could you perform packaging and testing? Encapsulation is packaging a chip in a plastic or ceramic casing to protect the chip and facilitate pin connections. Testing is conducting functional and performance tests on chips to ensure their quality.

The birth of integrated circuit chips cannot be separated from electronic technology's continuous innovation and progress. With the development of technology, the manufacturing process of integrated circuit chips has become more refined and complex, and the degree of integration of chips is also increasing. Modern circuit chips can incorporate billions of transistors with more substantial computing and processing capabilities. The birth of integrated circuit chips has strongly supported the development of electronic technology and promoted the vigorous development of information technology.